×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Ball Joint

Control Arm Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

96 Ball Joints found

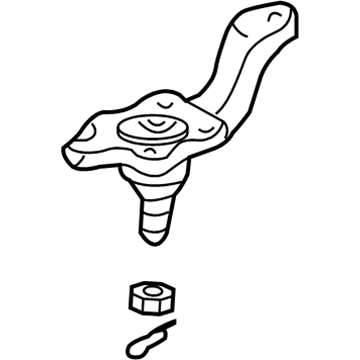

Toyota Upper Ball Joint, Driver Side

Part Number: 43360-39095$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper Ball; Suspension Ball Joint, Front Left Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Driver Side; Suspension Ball Joint; Ball Joint

- Position: Driver Side

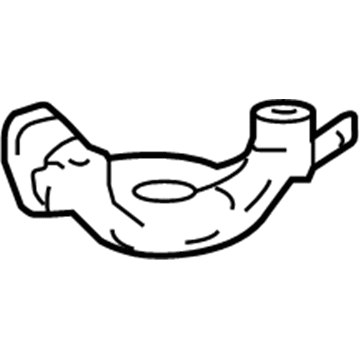

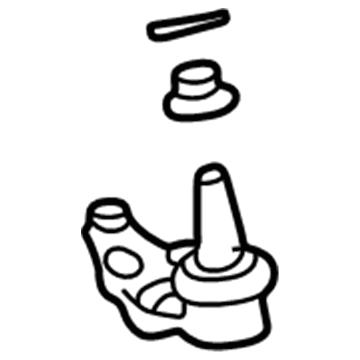

Toyota Lower Ball Joint

Part Number: 43330-09660$62.44 MSRP: $87.64You Save: $25.20 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Set, Lower Ball; Suspension Ball Joint, Front; Joint Assembly, Lower Ball, Front Passenger Side; Front Driver Side; Suspension Ball Joint.

- Position: Lower

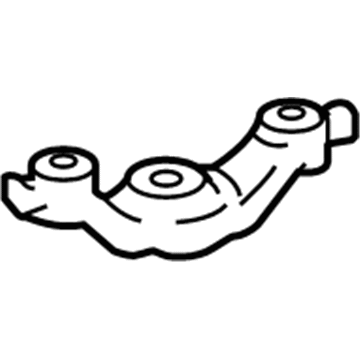

Toyota Upper Ball Joint, Passenger Side

Part Number: 43350-39105$70.50 MSRP: $98.95You Save: $28.45 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Front Upper B; Suspension Ball Joint, Front Right Upper; Upper Ball Joints; Joint Assembly, Front Upper Ball, Passenger Side; Suspension Ball Joint; Ball Joint

- Position: Passenger Side

Toyota Ball Joint, Lower

Part Number: 43330-09051$70.14 MSRP: $98.45You Save: $28.31 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front; Lower Ball Joint; Front Passenger & Driver Side Assembly; Suspension Ball Joint

- Position: Lower

Product Specifications

Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front; Joint Assembly, Lower Ball, Front Passenger Side; Front Driver Side; Suspension Ball Joint.

- Position: Lower

Toyota Ball Joint, Front Passenger Side

Part Number: 43330-39195$85.55 MSRP: $120.08You Save: $34.53 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint; Lower Ball Joint; Joint Assembly, Lower Ball, Front

- Manufacturer Note: RH

- Position: Front Passenger Side

Toyota Joint Set, Lower Ball

Part Number: 43330-29615$68.96 MSRP: $96.79You Save: $27.83 (29%)Ships in 1 Business DayProduct Specifications- Other Name: JOINT SET, LWR BALL; Suspension Ball Joint; Ball Joint

- Position: Lower Passenger Side

- Replaces: 43330-29405

Toyota Ball Joint, Front Passenger Side

Part Number: 43330-39845$75.59 MSRP: $106.11You Save: $30.52 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right; Lower Ball Joint; Joint Assembly, Lower Ball, Front Passenger Side; Suspension Ball Joint

- Position: Front Passenger Side

- Replaces: 43330-39775, 43330-39855

Toyota Joint Assembly, Lower Ball, Front Passenger Side

Part Number: 43330-49165$69.67 MSRP: $97.79You Save: $28.12 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint; Ball Joint

- Position: Front Passenger Side

- Replaces: 43330-49125

Product Specifications

Product Specifications- Other Name: Joint Assembly, Upper Ball; Suspension Ball Joint; Upper Ball Joints

- Manufacturer Note: LH

- Position: Driver Side

Toyota Lower Ball Joint, Passenger Side

Part Number: 43330-39815$143.46 MSRP: $203.08You Save: $59.62 (30%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint, Front Right Lower; Suspension Ball Joint; Ball Joint

- Position: Lower Passenger Side

- Replaces: 43330-39366, 43330-39367

Toyota Ball Joint, Passenger Side

Part Number: 43350-39045$84.83 MSRP: $119.08You Save: $34.25 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Upper Ball; Suspension Ball Joint; Upper Ball Joints

- Manufacturer Note: RH

- Position: Passenger Side

Product Specifications

Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint; Lower Ball Joint

- Position: Lower

- Replaces: 43330-19055, 43330-19056

Toyota Control Arm Bracket, Passenger Side

Part Number: 48625-60010$99.17 MSRP: $139.20You Save: $40.03 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Attachment, Lower Ball; Suspension Control Arm Bracket, Front Right Lower; Suspension Ball Joint Bracket, Right; Lower Control Arm Bracket; Lower Bracket; Attachment Kit; Bracket; Attachment, Front Lower Ball Joint, Passenger Side

- Position: Passenger Side

Toyota Ball Joint, Front

Part Number: 43330-29205$73.70 MSRP: $103.44You Save: $29.74 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint; Lower Ball Joint; Joint Assembly, Lower Ball, Front

- Position: Front

- Replaces: 43330-29140, 43330-29139, 43330-29136, 43330-09012, 43330-29135, 43330-29137, 43330-29138

Toyota Lower Bracket, Passenger Side

Part Number: 48625-04040$103.20 MSRP: $144.86You Save: $41.66 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Attachment, Lower Ball; Attachment Kit; Attachment, Front Lower Ball Joint, Passenger Side

- Position: Passenger Side

Toyota Ball Joint, Front

Part Number: 43330-29235$79.74 MSRP: $111.93You Save: $32.19 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint; Joint Assembly, Lower Ball, Front

- Position: Front

Toyota Lower Ball Joint, Passenger Side

Part Number: 48625-60020$118.78 MSRP: $168.15You Save: $49.37 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Attachment, Lower Ball; Suspension Control Arm Bracket, Right; Suspension Ball Joint Bracket, Right; Control Arm Bracket; Attachment Kit; Attachment, Front Lower Ball Joint, Passenger Side; Ball Joint

- Position: Passenger Side

Toyota Ball Joint, Front Passenger Side

Part Number: 43330-19066$71.09 MSRP: $99.79You Save: $28.70 (29%)Product Specifications- Other Name: Joint Assembly, Lower Ball; Suspension Ball Joint; Lower Ball Joint; Joint Assembly, Lower Ball, Front

- Manufacturer Note: RH

- Position: Front Passenger Side

- Replaces: 43330-12061

- Product Specifications

- Other Name: Joint Assembly, Lower Ball; Lower Ball Joint

- Position: Lower

- Replaces: 43330-29146

| Page 1 of 5 |Next >

1-20 of 96 Results

Toyota Ball Joint

Choose genuine Ball Joint that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Ball Joint for your Toyota ? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

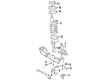

Toyota Ball Joint Parts and Q&A

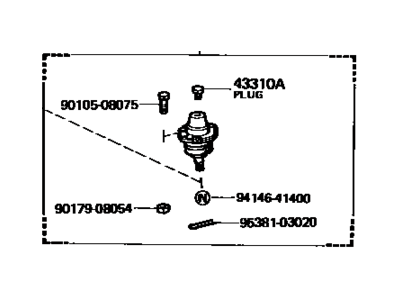

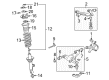

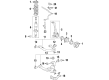

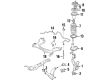

- Q: How to service and repair the lower ball joint on Toyota 4Runner?A:Service and repair of the lower ball joint starts with removing the front wheel while tightly setting torque to 110 Nm (1,150 kgf.cm, 83 ft. lbs.). The procedure begins with loosening the 4 bolts on the tie rod end to 80 Nm (820 kgf.cm, 59 ft. lbs.) while keeping them installed before removing the cotter pin and nut at 91 Nm (912 kgf.cm, 66 ft. lbs.). To disconnect the tie rod end from the steering knuckle use Special Service Tool: 09610-20012. The procedure for disconnecting the lower ball joint requires removal of the cotter pin followed by nutting it loose to 142 Nm (1,450 kgf.cm, 105 ft. lbs.) and then usage of Special Service Tool: 09628-62011 to uninstall the joint from the lower suspension arm while maintaining forward-facing orientation of the cotter pin hole. Disconnect the lower ball joint by lifting the upper suspension arm and steering knuckle then place them in a secure position. Test the ball joint rotation by moving the ball joint stud 5 times in each direction then apply torque using a wrench which should reach 0.1 to 2.5 Nm between 11 - 25 kgf.cm or 0.8 to 21.7 inch lbs during the 5th turn. After installation, check the front wheel alignment while conducting installation in the opposite direction of removal.

- Q: How to service and repair the ball joint on Toyota Tacoma?A:Service and repair of the ball joint begins by removing the front wheel while tightening it to 110 Nm (1,150 kgf-cm, 83 ft. lbs.). You should lift the lower suspension arm with a jack while you disconnect the tie rod end by easing the 2 lower ball joint set bolts to 160 Nm (1,600 kgf-cm, 116 ft. lbs.) without taking them off. Proceed with carrying out the removal process by completing the following steps: first remove the cotter pin along with the nut which needs to reach 72 Nm (730 kgf-cm, 53 ft. lbs.) torque but if the cotter pin holes become misaligned during installation tighten the nut an additional 60 degrees The Special Service Tool: 09610-20012 should be used for tie rod end breaking. To detach the lower ball joint you should first remove its cotter pin followed by loosening the nut to 110 Nm (1,100 kgf-cm, 80 ft. lbs.). Continue to tighten the nut beyond 60 degrees if needed. Special Service Tool: 09628-062011 enables lower ball joint disconnection before removing the nut, 2 bolts, and ball joint assembly. To check the lower ball joint rotation condition you should flip the ball joint stud 5 times before tightening the nut using a torque wrench on the 5th turn with a time span of 2 - 4 seconds until it reaches 0.1 - 3.45 Nm (1 - 35 kgf-cm, 0.8 - 30 inch lbs.). The procedures for installation proceed by relocating parts in the order opposite to removal.

Related Toyota Parts

Browse Toyota Ball Joint by Models

Tacoma 4Runner Camry Tundra Corolla RAV4 Highlander Prius Sienna Land Cruiser Pickup FJ Cruiser Sequoia T100 Avalon Celica Supra MR2 Matrix Solara Venza C-HR Grand Highlander Paseo Previa Prius Prime Corolla Cross Corolla iM Crown GR Corolla Mirai Prius V Tercel Van bZ4X Prius Plug-In Prius AWD-e RAV4 Prime