×

ToyotaParts- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Toyota Parts

- Scion Parts

My Garage

My Account

Cart

OEM Toyota Solara Thermostat

Engine Coolant Thermostat- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Thermostats found

Toyota Solara Thermostat

Part Number: 90916-03136$28.19 MSRP: $39.24You Save: $11.05 (29%)Ships in 1-3 Business Days

Toyota Solara Thermostat

Part Number: 90916-03090$27.59 MSRP: $38.41You Save: $10.82 (29%)Ships in 1-3 Business Days

Toyota Solara Thermostat

Choose genuine Thermostat that pass strict quality control tests. You can trust the top quality and lasting durability. Shopping for OEM Thermostat for your Toyota Solara? Our website is your one-stop destination. We stock an extensive selection of genuine Toyota Solara parts. The price is affordable so you can save more. It only takes minutes to browse and find the exact fit. Easily add to cart and check out fast. Our hassle-free return policy will keep you stress-free. We process orders quickly for swift delivery. Your parts will arrive faster, so you can get back on the road sooner.

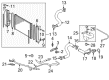

This paper focuses on the description of the Toyota Solara Thermostat that is a significant part of the car's cooling system often placed close to the radiator. The main role of the radiator is to cool the engine to the required temperature during its operation. Thermostats are categorized as closed-loop control systems due to the fact that they measure and regulate temperature set point in homes and industries. Different sorts of thermostats even in the past and present include the mechanical thermostat such as bimetallic strips and wax pellets and the pneumatic thermostats which utilize air full control tubes. Through such developments, systems in automobiles have been made to operate competently in their ability to control temperature thereby improving on comfort and effectiveness.

Toyota Solara Thermostat Parts and Q&A

- Q: How to service the thermostat on Toyota Solara?A:Engine coolant draining process must begin before the air cleaner cap assembly and its air filter removal. Disconnect the No.2 ECT switch connector and the engine wire protector from the water inlet and right cylinder head through the removal of 2 nuts. The water inlet pipe service requires removing both the bolt along with the O-ring from the inlet pipe to disconnect from the water inlet and left cylinder head. The water inlet and thermostat should be removed through 3 nut removal and gasket removal from the thermostat. Put the thermostat in water and monitor its heating process while verifying that its valve opening temperature falls within 80 - 84 degrees Celsius (176 - 183 degrees Fahrenheit) and its lift reaches 10.0 mm (0.394 inches) at 95 degrees Celsius (203 degrees Fahrenheit). The valve needs to be completely shut during temperatures under 40 degrees Celsius (104 degrees Fahrenheit) and you should switch the thermostat whenever specifications are not achieved. To install the thermostat place it inside the Water Pump with a new gasket while positioning the jiggle valve toward the upper stud bolt. Place three nuts on the water inlet using 8 Nm torque force (80 kgf-cm, 69 inch lbs.), follow by installing a new O-ring on the water inlet pipe leading to the application of soapy water before connecting the pipe to the inlet and tightening a bolt to 19.5 Nm (200 kgf-cm, 14 ft. lbs.). The procedure involves installing the engine wire protector and connecting the No.2 ECT switch while reinstalling the air filter assembly and air cleaner cap followed by engine coolant filling then verifying for leaks followed by a final engine coolant level check.

- Q: How to install the thermostat on Toyota Solara?A:Begin the 2AZ-FE cooling system thermostat install process by attaching a new gasket to the thermostat and placing it with the jiggle valve oriented upward but the valve can be adjusted between 10 degrees of the designated position. The water inlet needs two nuts to be tightened at 9.0 Nm (92 kgf-cm, 80 in-lbf). First secure the radiator hose inlet before adding the generator assembly and the fan and generator V belt. Complete the procedure by filling the engine with coolant then test for coolant leakage.